You should already know that edging machines are the most important machines to benefit glass, right? In addition to being the main ones, they are also usually the entrance equipment, that is, the first to be acquired by those looking to modernize the glassworks .

However, the types of glass edging machines can vary, with the glass double edging machine being a different example.

Do you know this machine? Do you know the differences that it presents in relation to a common polishing machine? That’s exactly what we’re going to talk about today! Follow the text below and learn a little more about these equipment and the possibilities that it can offer!

Common glass edging machine (vertical straight)

We started by talking about the polisher that you probably already understand at least a little bit: the vertical polisher. They are popular since any size and normal thickness of glass can be placed on them.

However, they have some counterpoints. As they are vertical, they require more effort on the part of the operator, in addition to presenting more risks in the handling of the glass piece.

The fact that they require that each face of the glass be cut individually also harms, as it slows down the process.

GLASS DOUBLE EDGER

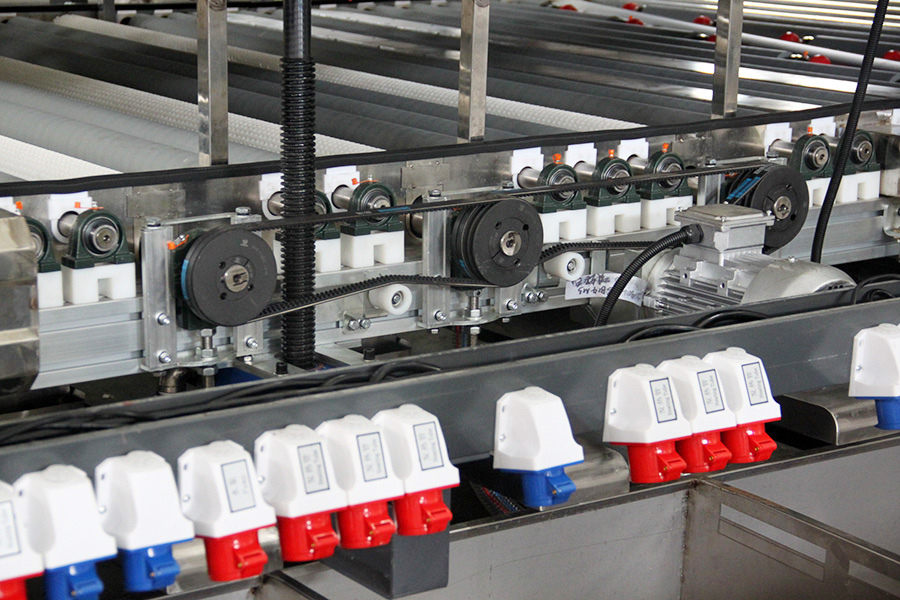

A glass double edger, however, solves these two problems. To start, the glass goes through the process in a horizontal position, which gives more stability and reduces the risk of accidents with operators to practically zero.

Another differential that should be highlighted regarding the bilateral polishing machine is the characteristic that gives the name of the machine. Unlike vertical straight equipment, here the polishing is done on two sides simultaneously, which reduces the polishing time in half.

To get an idea of the capacity of these machines, some bilateral polishers have the ability to grind up to 12 meters of glass per minute.

The differences between glass double edging lines

A trend that has been observed in the market for some time now is the assembly of double edging lines with two double edging machines to facilitate all the work of operators and to optimize and accelerate the process as a whole.

If you want to know a little more about this, we have a video to show the full process:

Although it has its advantages, the negative point of this line is the horizontal space it occupies, since it is necessary to join 4 machines side by side. This system will only be viable in productions with a lot of available space.

On the other hand, even though it is faster and occupies less space, the faceting line with double edging lines also presents a great disadvantage. Maintenance on one of the machines causes production to be reduced by 50%, while in the case of common straight line edging machine the reduction is only 25%.

Double edger V.S. Vertical straight edging machine – Which one to choose?

As you can see, double edgers are faster. Therefore, they are the most recommended for those who have a large production and need to prioritize speed in edging As in most cases when we talk about the improvement of a glass, the best alternative will depend on each glazier and their level of production.

However, for whatever your option, TECHWIN can be your partner! We can provide both glass double edgers and glass straight edging machines. Please write to us and get more info: franky@fstechwin.com