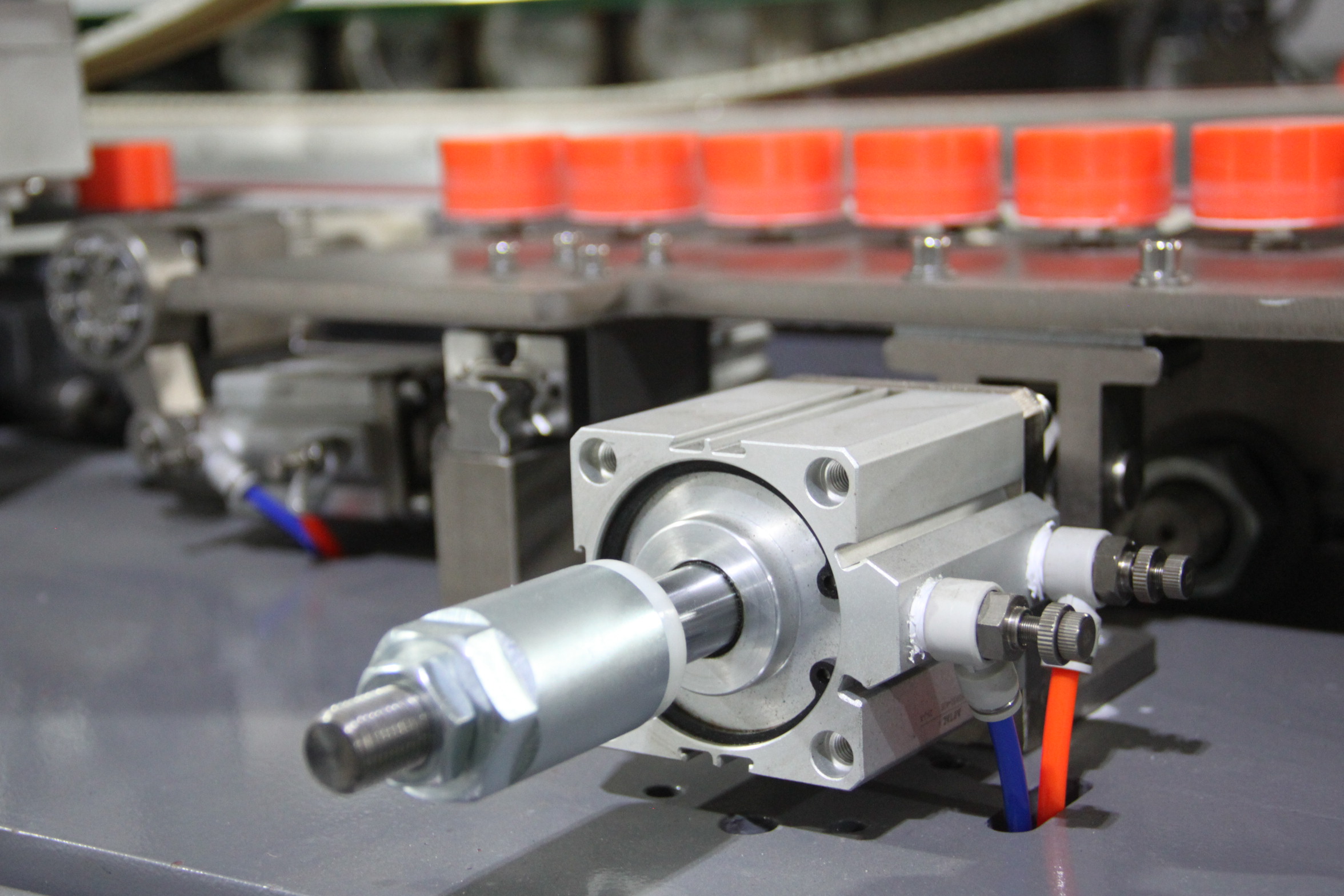

Glass double edging machines provided by Techwin are of top quality from the top factory, whose machines have been widely acknowledged as the first ranked machines in China.

TECHWIN offers fully automatic double edgers controlled by servo motors, as well as semi-auto edgers for easy operation and precious processing. The stable machine performance and extraordinary processing efficiency account for their smart choices and success.