With the features of high transmission, ultra clear, waterproof and high safety, solar glass has become one of the important part of for solar panels assembly.

Solar glass are mainly made by patterned glass. Solar penal consist of top and bottom glass. Therefore, the processing procedures for top and bottom glass are a bit different.

–

Processing procedures

–

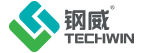

For top glass, the production chain is as below:

It’s easier and faster to process top glass. Now most of the Chinese solar glass manufacturers will apply two-layer coating to improve the transmission rate of the glass.

–

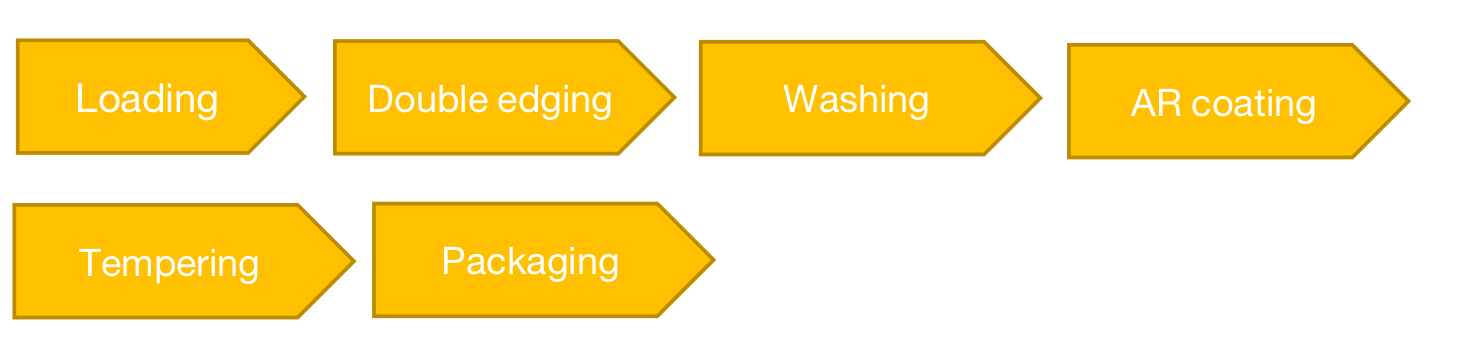

For bottom glass, the production chain is as below:

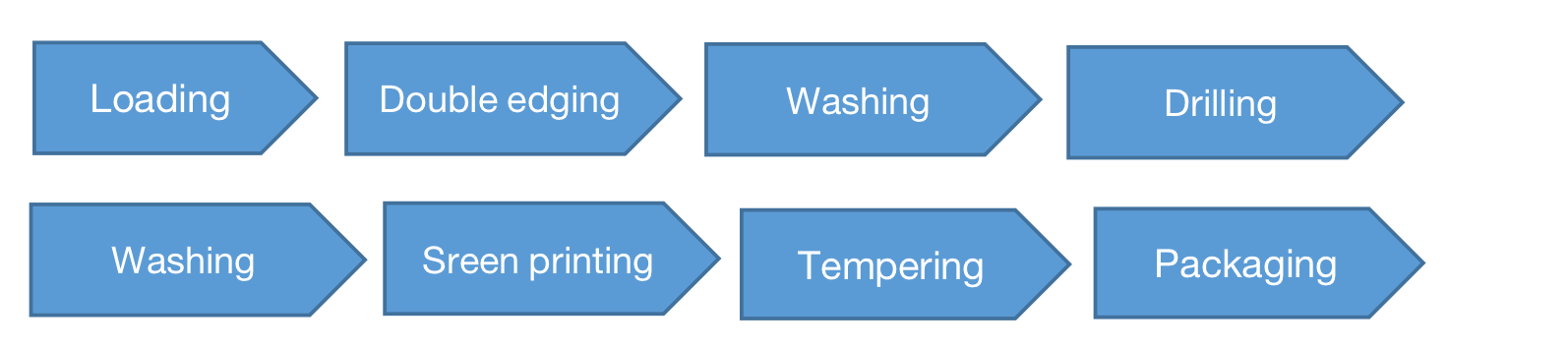

In real production, most cases are these two processes combined in one production line. Then the full process will be as below:

–

Processing machines

–

Now let’s get to know more on what specific machines are needed for the lines.

Loader: The raw glass has cut into different needed sizes from the glass suppliers, no cutting machines are used in this line. The first step is to load the glass. The loaders can be standard loading machines or robots. Both can meet the needs. A rotary platform to place the glass racks can be set in front of the loader.

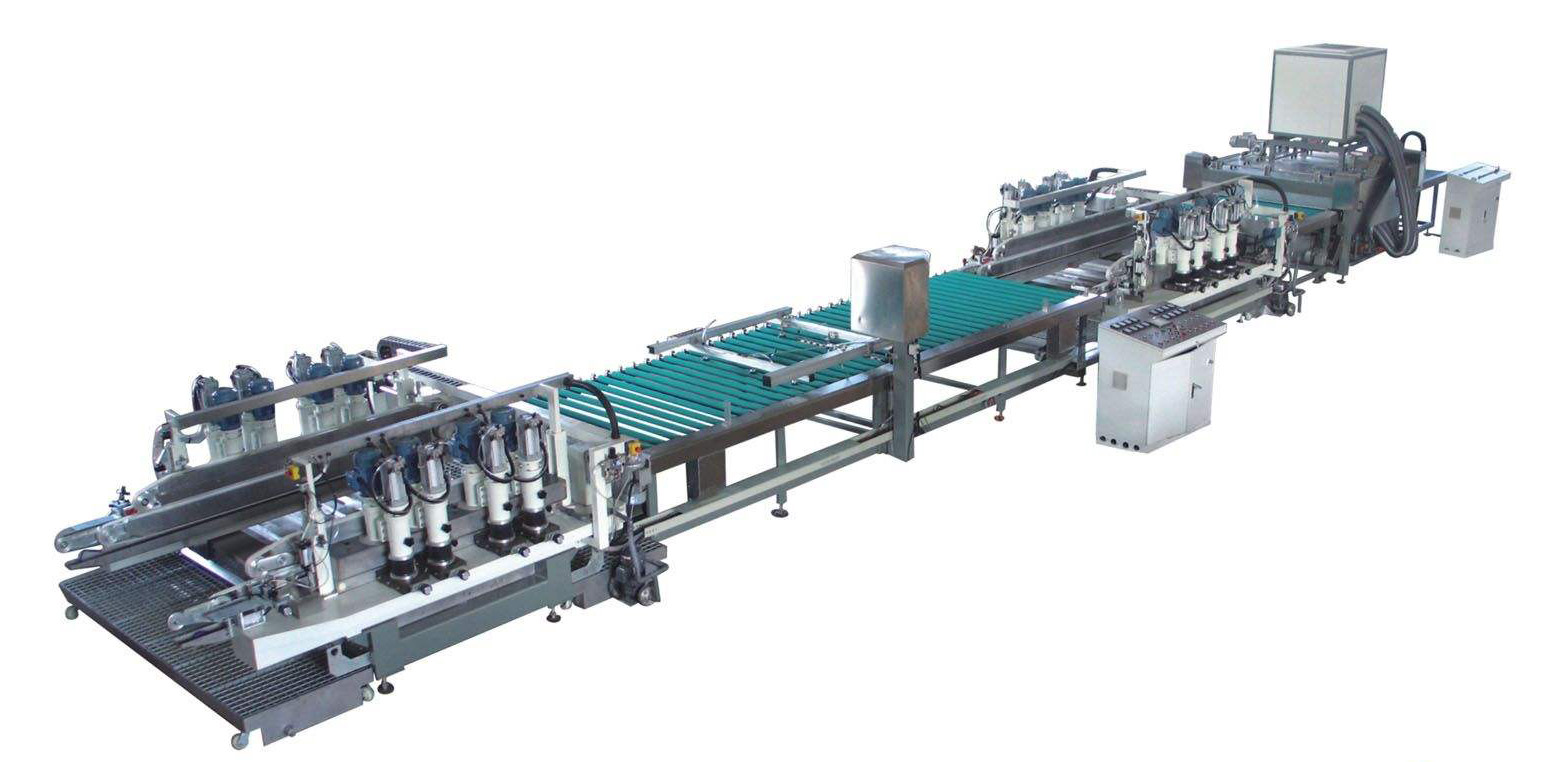

Double edgers: The double edgers are pencil edgers. These edgers are with 6 or 8 motors for the first edger. For the 2nd edger, it should be with motors for corner grinding. The first edger can process max. 2500mm wide glass and the second one can process 1500mm or 1400mm wide glass.The turning table used between the two edgers better with wheels dip in water for self cleaning.

Washing machine: There are several machines used the solar glass processing line. The washers should be with high configuration models. For example, the one used before the coating line is better to be with flat brushes for better cleaning. Some will use two normal washing machines to pursue the same effect. The one after the tempering machine should be a very high speed one, with six pairs of air knives or even more, to dry the glass quickly before packaging.

Drilling machine: The drilling machine used for bottom glass are online drilling machine. Laser glass drilling machine is the first option for most glass fabricators, it’s with high speed and high accuracy. Traditional glass drilling machine can meet the needs if the output of the line is not high. The mechanical drill can be placed directly after the double edgers, glass can be washed after drilling. For laser drilling, glass should be washed before positioned and drilling.

AR coating machines: The AR coating machines includes pre-heating oven, positioning table, AR coating machine, leveling machine and IR dryer. Anti-reflection liquid will be coated on the glass surface by a roller coating machine evenly. The roller coater will be placed in the clean room. After heating, cooling and finally tempering, the transmittance of the solar glass will increase by 2% to 2.5%.

Screen printing machines: The screen printing machines in this line are mostly used for bottom glass. It includes positioning table, screen printing machine and the dryer. The printing machine has a shuttle system that is driven by servo motor to increase the production capacity.

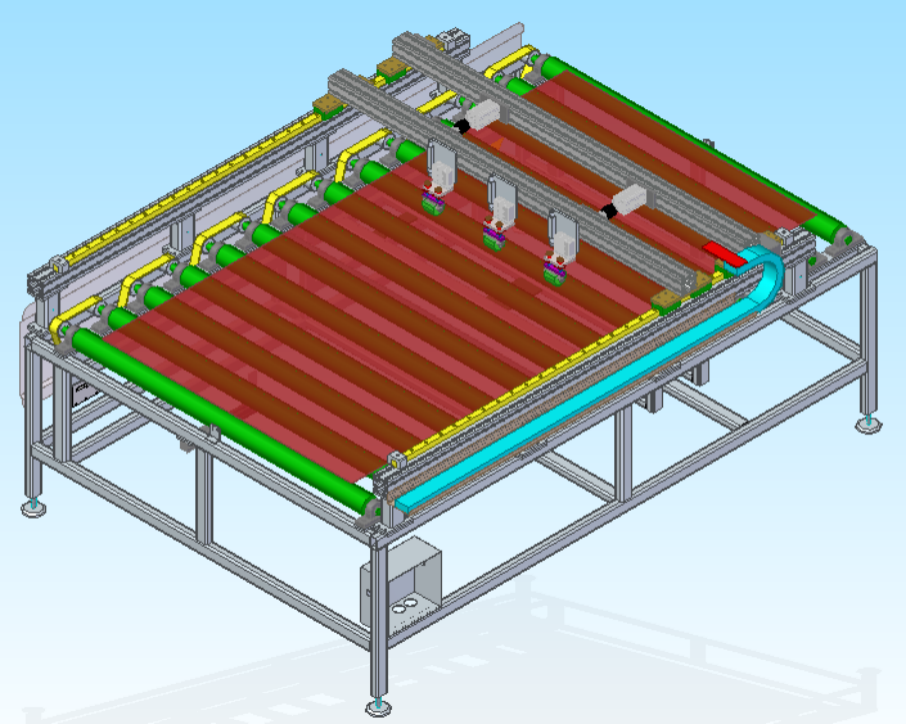

Conveyors and stackers: Many conveyors are used in this line. The function can be buffering, positioning or inspection. For example, an inspection table can be used after the laser drilling machine, before or after the tempering machine to check if the glass is qualified. Stackers can be used before the printing or the tempering machine.

Tempering machine: Solar glass are mainly made by patterned glass which may have bubbles and lead to high self breaking rate. And solar glass is thin, it has high request on the quality of the tempering machine. A stable furnace means non stop production. We don’t provide tempering machine, if you need tempering machine, try to find someone who had rich experience for solar glass projects.

–

Production line layout

–

In China, the larges processing factories use straight processing lines. While the smaller ones prefer U shape lines. In normal case, the tempering machine is the key of the productivity of the line. The continuous processing line is most popular in the market for solar glass processing. The rest of the machines in the line should be capable for high processing speed too.

–

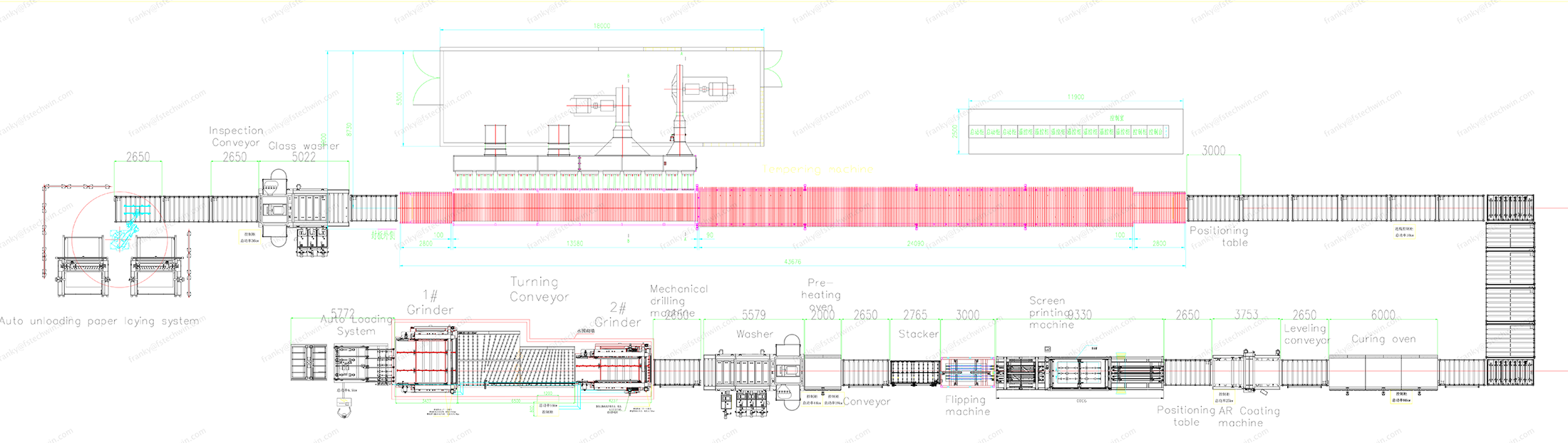

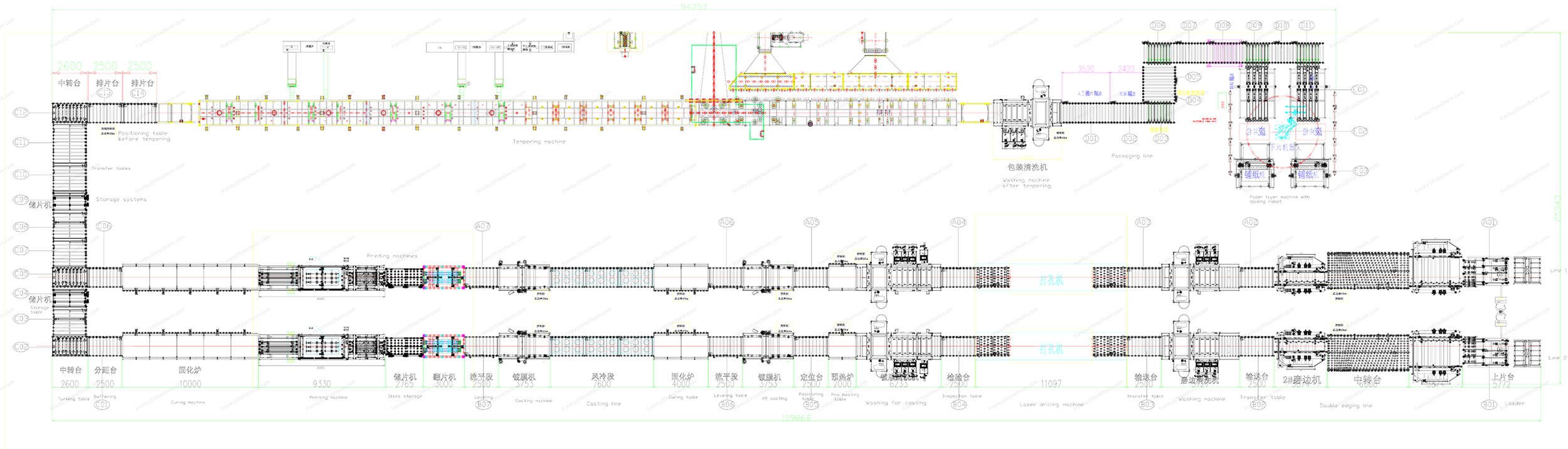

The whole production line for top and bottom glass can be like below drawing.

This is the most basic and economic line, the drilling machine used in this drawing is mechanical drilling machine as the speed of this line is not very high. Stacker used before the printing machine to avoid glass crashes because the screen printing line is with not too fast processing speed. The screen printing and AR coating machine shares the same heating and cooling line to save costs and space. There is a positioning table before the tempering machine, glass will be positioned automatically on this table. After the tempering machine, there is a washing machine to cool the glass. An inspection table used after the washing machine to check if any defaults on glass before packaging. An unloading robot at the end to move the glass to the paper laying machine for packaging.

–

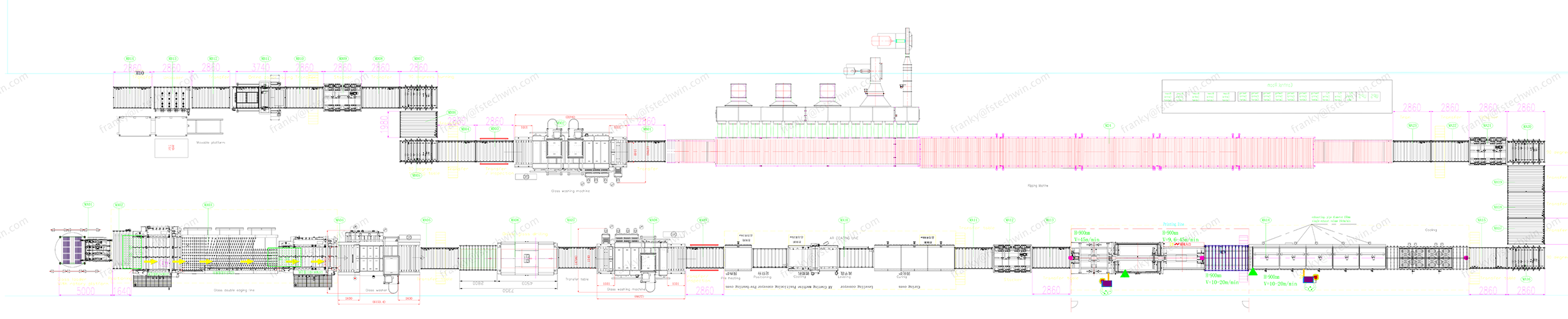

If you have more budget, below line is a better option. A laser drilling machine is used, the glass should be washed before and after laser drilling. The AR coating line and screen printing line have their own heating and cooling system to avoid the risks of stopping production caused by abnormals in one line.

Above two cases are with one edging line to feed in the tempering machine. If you want more output, you can use a longer tempering furnace and two or three edging line feeding in, just like below:

–

Two separate edging — washing — laser drilling – washing — AR coating (two layers) — Printing lines will combine to send glass to one furnace. This line can produce 400-460 pcs of 1400*2100mm glass per hour, productivity is different due to the different glass thickness. Now in the market, normally the max. solar glass size is no more than 1400*2500mm, the machines are designed as per this size. The 1st double edger will grind the short edge then the back stream machines are with processing capacity for max. 1400mm wide glass.

–

As mentioned before, the tempering machine is the key for the output, if the heating zone of the furnace is 54-60m long, it can fast enough to process glass from three edging lines. If its heating zone is 30-48m long, two edging lines can feed in the oven. If its heating zone is 21-24m long, then one edging line can match its speed.

–

Almost all of the solar glass processing lines are customized solutions as per the customer’s factory size, specific request and budget. If you want to plan a solar glass processing plant, please contact franky@fstechwin.com to get a suitable solution.