As you consider purchasing a glass washer for washing machine and drying flat glass. You might take 5 minutes to read this buying guide so as to make better informed purchase decision.

Size

The first thing you need to take into consideration when you decide the washer is the max. glass processing size in your plant. There is a range of width for washers as options, the common sizes produced by Chinese manufacturers are as below:

800mm, 1000mm, 1200mm, 1600/1700mm, 2000mm, 2500mm, 3000mm or even 3300mm.

Remember that the glass has long and short sides. Better choose to wash the short side as width. For the big washers up to 2000mm or above, make sure the loading and unloading zone is long enough to hold the long pieces. Anyway, customized length of the washers are available for most suppliers.

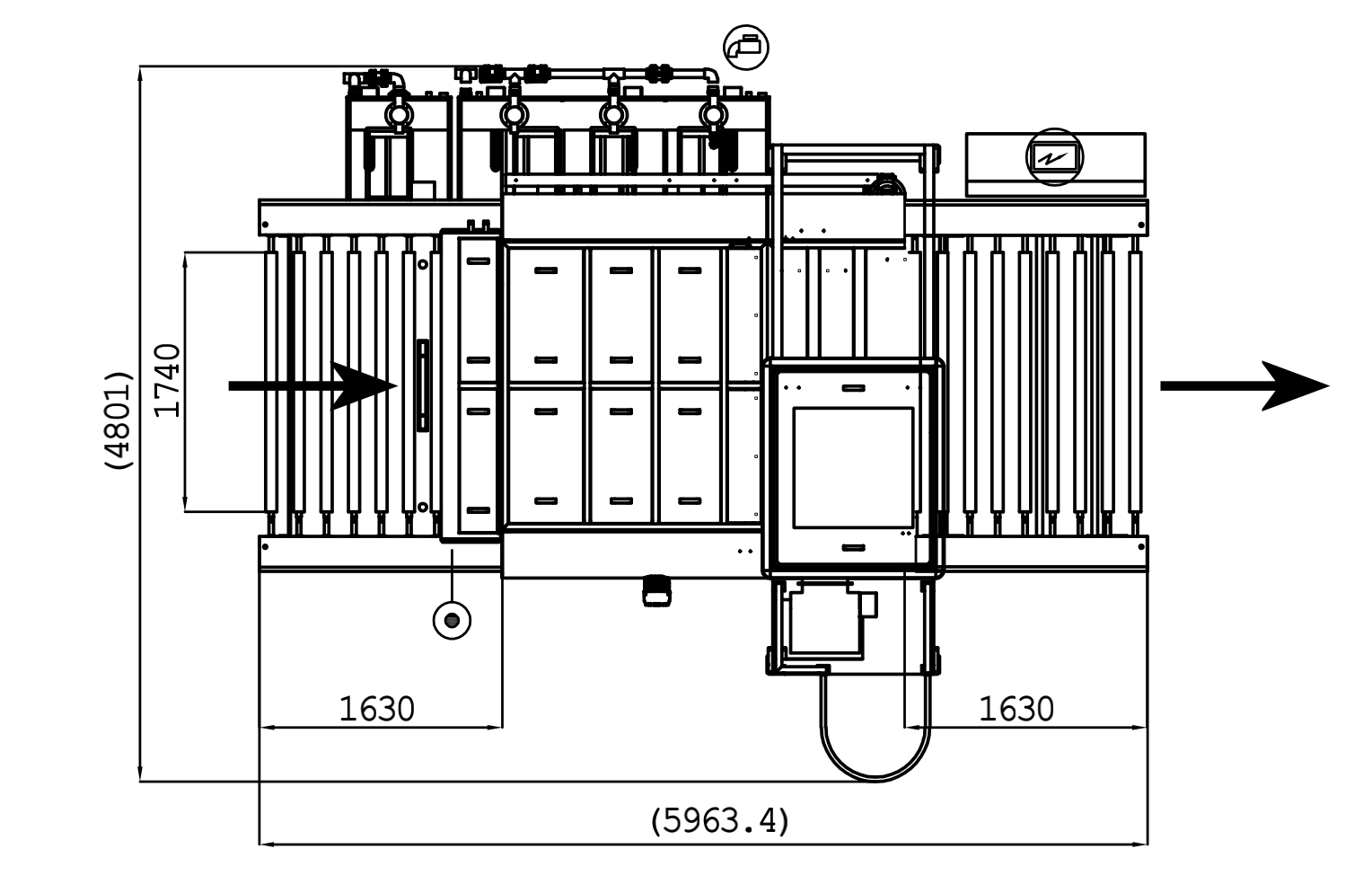

When we talk about size, we also need to look into the overall dimension of the entire washer. And you will need a machine layout from the supplier and to check if you have enough space to place the washer.

Horizontal V.S. Vertical

There are two systems to wash the glass: horizontal and vertical.

Horizontal machines are most popular among glass fabricators. They are stable and easy to load glass. These washers are widely used in double edging lines, cutting lines, laminating lines, printing lines or tempering lines. Of course they can be stand alone machines. Why should we choose vertical washers when the horizontal ones are efficient and long lasting?

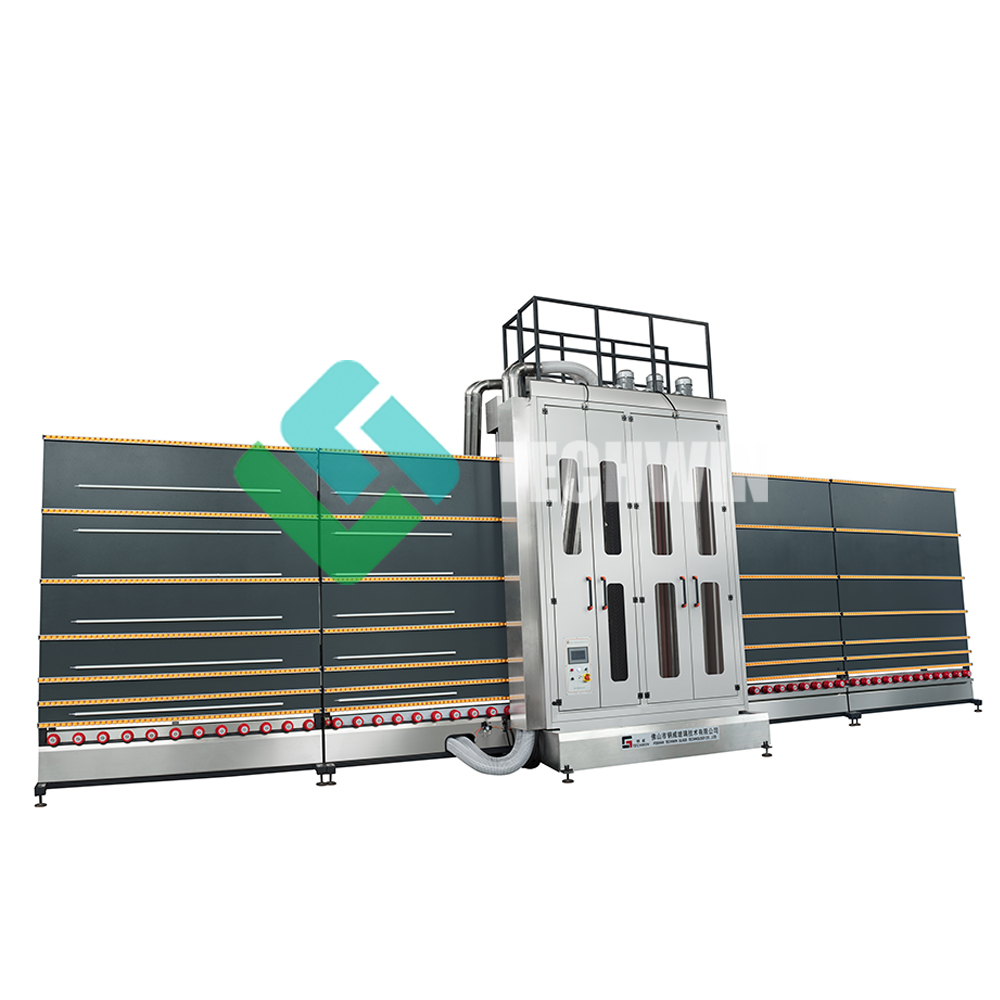

In some lines like IG lines, vertical drilling lines or vertical CNC working lines, vertical washer is must have item. For some fabricators who have limited space in their workshops, vertical washer is the better option as it can save some space.

Sponge drying V.S. air knives drying

Some new-in-industry customers may get confused when suppliers ask, which drying method do you prefer: sponge or air knives?

Sponge drying means to dry the glass with sponge rollers. Sponge rolls will be set after washing zone, they are wet and when glass passes, the rolls will squeeze the glass and absorb the water on both surface. Several heating elements set after the rolls and a blower will blow the hot air to eliminate the water on glass.

The washers with sponges are mostly for glass under 1600mm, advantage of these washers are: small, economic and quiet. They occupy little space and affordable, and most people like it because they don’t make so much noise as the air knives models. And it can process small size glass. They are popular among the new factories, appliance glass factories and other factories who processing small size glass.

The main headache for owner of the sponge washers is you need to replace the sponges every 6 months to 8 months, and it’s not a very easy tasks. Second point is most sponge washers made in China can only adjust thickness manually, unlike the air knives models which has automatic lifting. And you don’t take the sponge washer into consideration if you want high output. The speed of this type is slow, no more than 5m/min.

An important point to use the sponge washers: the sponge rolls should be cleaned once per shift. If not cleaned properly, remained oil from glass cutter or printing machines will shortened the life of the sponges, they will get hard and can’t absorb/dry water on glass well.

Air knives models are best sellers in the market. A blower placed on the machine top will provide strong air flow to the air knives inside the machine to dry glass. There are straight and angled air knives. The straight ones are to remove water on glass surface and angled ones are for water at the edge. So basically the one with angled knives can dry glass better.

The air knives are made with aluminum and stainless steel so long durability is guaranteed. For maintenance, you only need to clean the debris on the gaps of the knives once every 10 days, this saved a lot of time and labor. It’s the only option for processors for big architectural glass.

Majority of these washers have motorized lifting to adjust thickness. With PLC and HMI set, they can be easily integrated into production lines and achieve synchronous speed and thickness with other machines.

Noise is the key point to annoy the owners of air knives washers. Good manufacturers like TECHWIN can keep noise of the 2500mm model around 80db, but many others washing machines has 85db or more. To reduce noise is not only about making better seal on the blower cabinet, but also the air flow system under the drying zone. The design of the air knives are very important too, the gap width on the air knives matters a lot!

If you hope to create a more comfortable environment to your employees, make sure to know what db of the washer. Ask the suppliers to provide some test videos or better to check at site and you can feel authentically.

Speed

When you have determined your mind to go with an air knives model, the next problem you may face is the quantity of air knives.

The quantity of brushes and air knives in the washer decide the output capacity, means speed. The more brushes and more air knives, of course the better the washing and drying will be. But it’s not necessary to have extra ones unless they can meet you needs.

For stand alone machines, the maximum speed 8m/min is enough. For four side edging lines or fine edging lines, 12m/min is good. Normally 2 pairs or 3 pairs of air knives are used for those washers. For high speed edging lines, max. speed should be 16m/min, at least 3 pairs of air knives should be set in these washers.

Brush type: Roller brushes and cup brushes

All the washers for flat glass are with roller brushes, but some are also with cup brushes for polishing. The cup brushes can be cleaned and polished the glass perfectly, normally used for washers before coating or digital printing.

Budget

For most of buyers, the purchase price of the glass washing machine seems to be of their biggest concern. If you are looking for the smallest investment which falls within your tight budget frame, opting for a sponge model seems to be the best move.

When you do some sourcing for a washer in China, you may feel surprised on the big differences from different suppliers. Many overseas customers have heard or have been to Shunde District of Foshan City, numerous glass machine manufacturers built their base here so you can find whatever you need for your glass machines here. Jinan in Shangdong is also known among customers. If you need high quality washers then you can buy from Shunde but if your budget is limited you can turn to suppliers in Jinan. The machines there are with incredibly low costs but long durability and stability are not guaranteed.

If you are looking for a high performance glass washing machine, please send your inquiry to franky@fstechwin.com.

Our sales specialist will get in touch with you in 24 hours.