Many people will have concern when it comes purchasing glass machinery from China. In the past, low quality products flooded the market. But this does not mean that China only produces cheap quality products, it has a lot more to offer. It actually caters to all kind of buyers.

Today, China is considered to be one of the top glass machinery exporters of the world. More and more customers choose to buy from China, from single machine to a custom automation production line.

There are so many glass machine manufacturers in the market and you may not know how to pick the reliable ones, below are tips that helps to pave the way and save your time.

1. Types of glass machines and their locations

The glass machinery manufacturers in China become to focus on one or two products, in order to be more professional in it. You should be careful if you find a supplier who can provide every machine you need, it could be a tragedy if you work with them. Bellow are the machines you need for your glass processing plant, and they could be from different manufacturers:

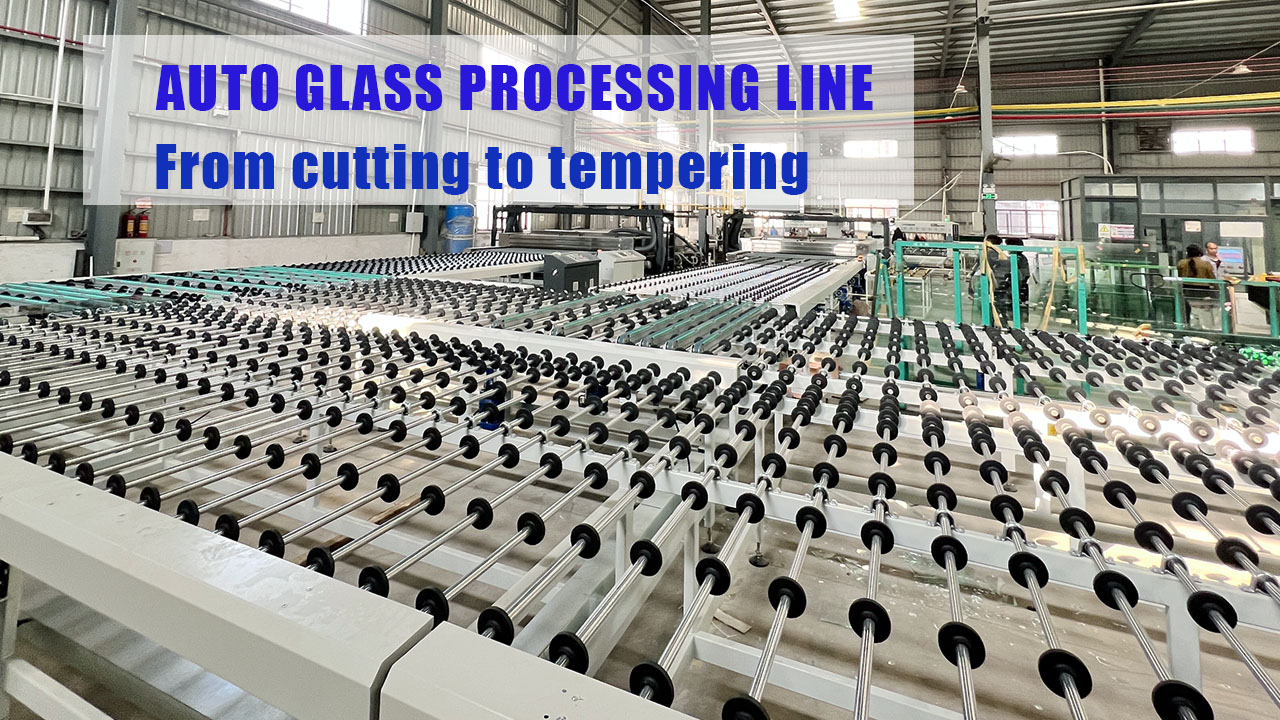

Glass tempering furnace. It is a big investment and also the key for successful business. You should be very cautious before making the decision.

Choose a famous brand, the brands you have heard or the machines your peers are using. But remember, don’t go for a machine that only has beautiful looking. Some manufacturers only pay attention on the appearance of the machine but function and performance are not good. Maybe 50% of the cost is for the image developing companies they hire and the fancy advertisement they promote.

Focus on the R&D team, check how many patents they have and see if there is any breakthrough on technology they have made. Make sure it is an energy saving furnace and it’s easy to operate. What’s more important, choose a supportive factory who can react fast to your questions. Even some factories have agencies locally in your country, they will not fly directly to your site when problem occurs. Working efficiency is an important term to judge the manufacturer. Make sure they will give respond to you quickly when you have after sales issues.

There are two main locations for tempering furnace, Luoyang city, Henan Province and Foshan city, Guangdong Province. Among these factories, there are only several worth to buy if you care about quality.

Southtech(South Glass Technology Co., Ltd) could be the one who is with highest cost performance. The two owners of the company are technical experts in the industry and invest large amount in product development every year. In 2014, the first 2mm continuous flat glass production line by Southtech was successfully put into operation which opened a new era for tempering thin sheets.

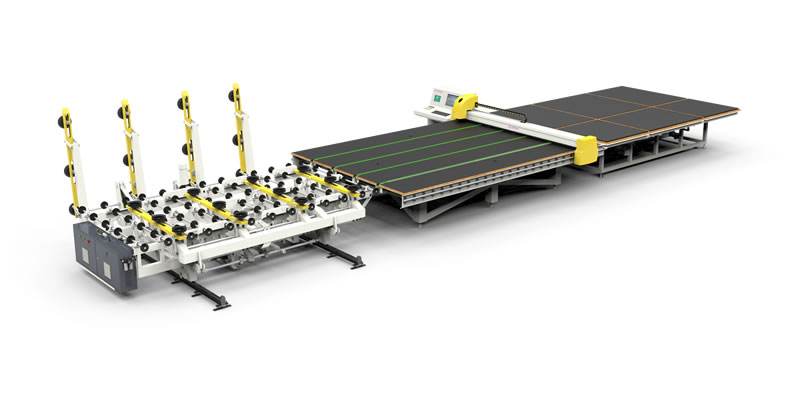

Glass cutting machines. There are many ways to cut glass, for raw material, CNC glass cutting machine is the best option. Precision is the key for this machine. Then it comes to speed and maintenance. Manufacturers for this type of machine mainly locate in Anhui Province.

Several standards to judge if the machine is with quality components:

*Electrical parts, like motors, are from famous brands.

*Guide rails should be imported, or at least from Taiwan.

*European or US software system.

*With protection against damages during the separation process.

For laminated glass, the cutter should have function of edge deletion and coating protection.

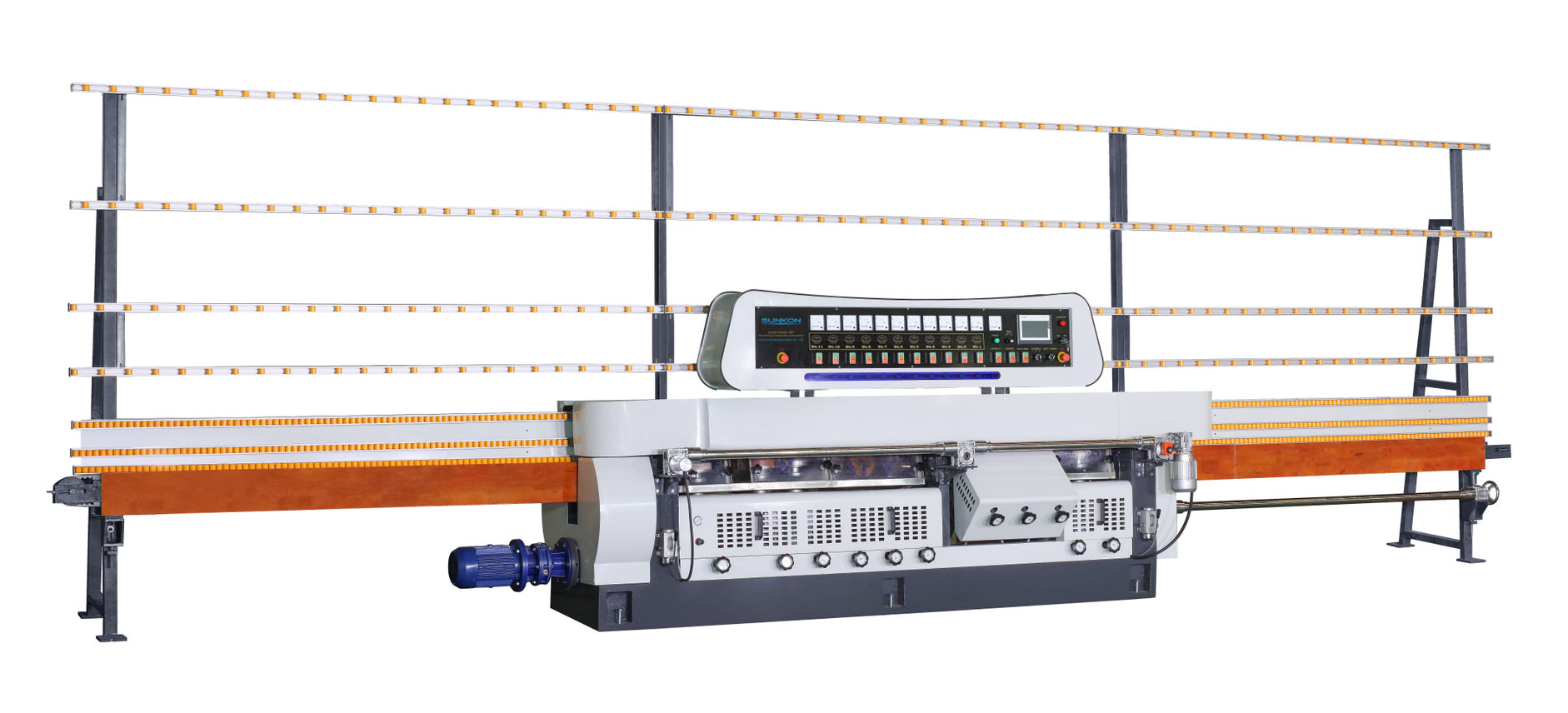

Glass edging machine. Straight line edging machine is a must have machine for glass fabricators. And of course double edgers are also popular. Sometimes you also need to polish round edges or glass with irregular shapes. There is a place you should remember: Lunjiao town, Foshan.

No matter straight line edging, beveling, double edgers, shape chamfering or high speed seaming machines, from high quality to cheap ones, you can find in Lunjiao, which is also called the Town of Woodworking and Glass Machinery. Of course, there are a few qualified manufacturers for edging in Zhongshan, a city nearby.

Many suppliers provide OEM service, maybe the machine you buy directly from the local distributors in India or America, with their own logos printed on the machine, are all from here.

Glass washing machine. It’s the basic machines for glass plants. There are two main types, one is to dry glass with sponges and the other is with air knives. It seemed to be a simple machine with not high value, but if you made wrong decision on it, it will cause big trouble. Qualified manufactures for this machine mainly in Lunjiao, Foshan or Shenzhen.

Remember do not to buy this machine from Shangdong province, the suppliers there will offer machines with incredibly low price but it will cost you more for after sales problems.

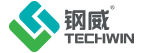

Techwin(Foshan Techwin Glass Technology Co., Ltd) maybe the only glass washer producer who owns its metal processing center and rubber rollers workshop.

The rubber rollers made in house are with 3mm thick seamless tube while many other suppliers will use 2mm thick welded pipe. Rollers will get bent for two or three years with welded pipes. Rubber content for Techwin’s roller is up to 40% even they have been used for 5 years, the roller surface will be elastic, unlike others, rubber will fall off after one or two years. Glass powder will stick on the holes and scratch glass. Then you need to stop production and wait another 2 to 3 months to get new replacements.

Besides, machines from Techwin have the reputation of stable and long duration. That’s because the machine chassis is quite tough and strong, it’s for heavy duty jobs. Unlike some factories, use thin stainless steel and light structure to reduce costs.

As production line is a trend, Techwin has rich experience on working with different edging machine manufacturers, to integrate the washing machine into production line. Communication test between washer and other machines will be carried out before shipment to make sure they can cooperate well with each other.

Glass drilling machines are designed for drilling flat glass, mostly from 3 to 20mm thickness of flat glass. It’s widely used for shower door glass, window glass, furniture glass, appliance glass, ect. The traditional double headed auto or semi-auto drilling machine are affordable and easy to source.

Now CNC drilling machine becomes popular, it’s with PLC and touch screen. Servo motors controls the travel of X/Y/Z axes for faster and more precision jobs. Single and multi stations are as option.

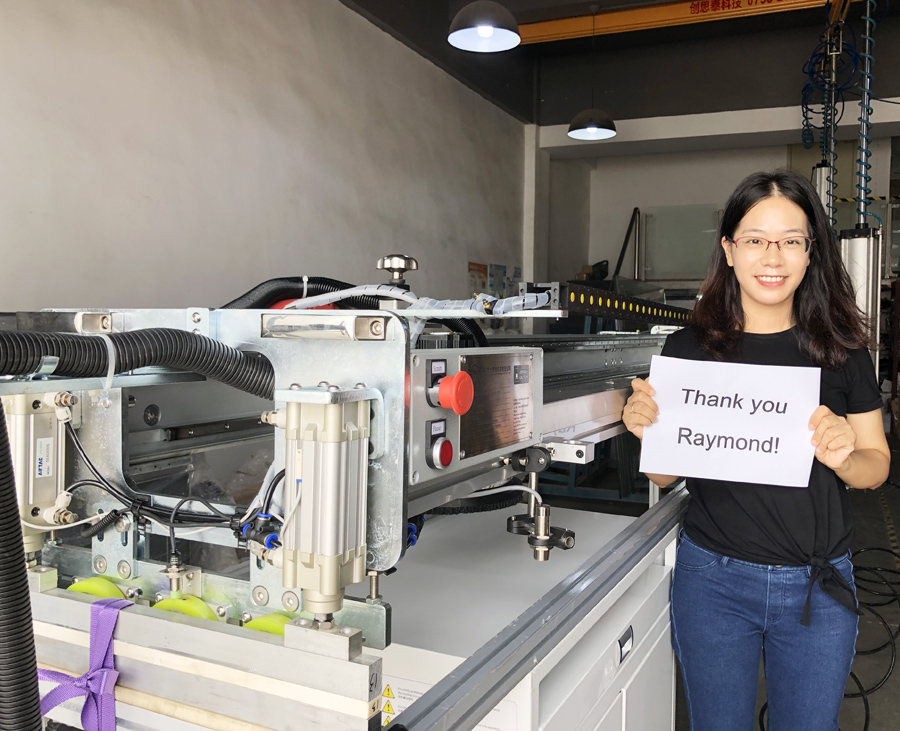

For fabricators who needs online drilling, automatic drilling production line will be a good option. Online drilling means the drilling process can be done in a production line. The flow can be like this — Automatic loading machine — double edger — transfer table — double edger — glass rotatory table(if necessary) — automatic glass corner edging machine(if necessary) — drilling machine — glass washing machine — unloading machine. Of course, it’s not so easy to set up a line like this, the machines are from different factories so it will take certain time for thorough communication between the suppliers to ensure the line runs smoothly.

Both offline or online drilling machines can be found also in Foshan or cities near by.

IG line of equipment includes components such as a butyl extruder, two component extruder, automatic spacer bender, desiccant automatic filler, automatic Low-E film deleter, spacer cutter, spacer conveyor, rotating table, hydraulic elevator, salt loader, and more.

No matter what degree of automation is desired, whether relatively simple, semi-automatic or highly automated, IG production line manufacturers in Beijing and Jinan can take care all your needs. Suppliers in Beijing are with higher quality and of course price will be comparatively higher. But you will get what you pay for. If you have limited budget and you are not so picky for quality, the machines in Jinan will make you satisfied.

Laminating glass production line. For PVB lamination line, it is integrated with loading and unloading tables, horizontal glass washing machine, assembly station, pressing and convectional heating sections.

There are only a few manufacturers for laminated glass machines in China. For PVB laminating, the most famous three brands are in Shenzhen, Shangdong and Liaoning. For EVA laminating, you can check the ones in Bejing, Shangdong and Guangzhou.

If you want to know more details or are interested in other machines like sandblasting machine, CNC work centers, glass handling machines or tools, please contact franky@fstechwin.com and I will provide advice and solutions to you.

2. Ways to know and access the manufacturers

When you have clear goals on what to buy, you may start to source to get a list of potential suppliers. You can get to know them by google, alibaba.com or trade fairs.

Some suppliers have attracting pictures on their web or in alibaba, but be careful, not all of them are manufacturers. Some are trading companies who has good photoshop skills. They even put their own logo on the factories which they download from the internet.

Normally, the real factories will have pictures for their workshop, where machines are with their logo, or employees in clothing with logo printed. You can also search the company name, if they work with machinery distributors in different countries, they must be real manufacturers.

Trade fairs are good ways to know suppliers. China Glass is a big event for all glass machinery and accessory manufacturers in China, it will be held in Beijing and Shanghai by turns, at the end of April or May every year. You can also know them at the local trade fairs, like Eurasia Window, Door and Glass show(Turkey), Mir Stekla(Russia), Glasstec Dusseldorf(Germany), GLASSBUILD AMERICA(US) and so on. Only qualified manufacturers who have good business can afford the high expenses to attend overseas exhibitions.

Next, it’s time to talk to them or visit them. If you are going to Foshan, you can fly to Guangzhou, it’s about an hour drive from Baiyun airport to Foshan. If you are heading to Shangdong or Jiejiang, you can fly to Shanghai and take the high speed trains to the cities to, and between, the provincial cities.

3. Try to get proposals with detailed information

You will get technical sheets from the suppliers. The one who can provide with most details or information could be the most potential partners. At least they care about what to present to customers and they did a better and more careful job than most of others. Attitude is important. Below are basic information that should include in the proposal:

- Modelnumber

- Definition of usage

- Functions

- Pictures of the machine

- Stainless steel grade (SUS 201, 304 or 316)

- Voltageand frequency(Make sure the parts are really in the voltage of your area, instead using a transformer for the whole machine)

- Mechanical parts like bearings and machine frame

- Electrical parts(Motor, reducers, pumps, electrical componentslike inverter, PLC and etc.)

- Total power

- Speed of the machine

- Control systemor software

- Certification (e.g. CE Machine or with CSA/UL parts)

4. Visiting the factories

Meeting your supplier for the first time is a very important part of the sourcing process. Locate and group the factories you need to visit by area. Then arrange the trip according to the location and dates provided by the suppliers. It is usually possible to visit two factories in one day if they are in the same city.

Inform the factory and let them how about your schedule and arrange local transportation beforehand. Prepare a list of questions and expectations for you supplier will help you get the most out of your visit. After all, meeting face-to-face with a supplier to ask questions and resolve issues related to manufacturing is typically a major reason for buyers making the trip.

It would be better if you can talk to the owner of the factory face to face, their concepts and knowledge have much to do with their products. Walk through the factory, check conditions of the factory – are the materials stored properly? Is it clean & well organized?

Do not only visit the manufacturers, especially for large machines like furnace. Go to see existing companies using their equipment nearby, to see if the machine still works well after years and check the glass produced by these machines.

5. Installation, Service and Maintenance

Most of the glass machinery suppliers offer overseas installation by sending technicians to customer’s site. However, the problem is that these factories do not have sufficient employees. Try to figure out how long they can send technicians to your site after containers arrived and what kind of after sales maintenance advice they can offer.

Machines require maintenance, repairs and spare parts. It would be better if the company has special department who takes care of spare parts service. In case your production line stops only because of a small electrical component, you can check what free spare parts they offer and you should storage enough backup for easy wear parts.

6. Try to negotiate for the right deal

Any good business relationship is focused on finding the right business deal. When you have a clear understanding of your own weaknesses as well as strengths and the priorities of your suppliers, it can really help you in negotiating the perfect deal. The Chinese usually believe in having a good relationship with their prospective clients. These relations need to be built on mutual benefit and interest.

7. Always try to have a clear contract

Always have a clear contract regarding the payment as well as delivery terms. When you use internationally agreed incoterms that are International Commercial Terms, it can assist you in reducing the risks of having misunderstandings or delivery issues. Moreover, your contract should also cover the payment that is required and the currency in which the payment would be made.

Before you place an order, confirm the specific warranty terms set by the supplier in the contract. Warranty terms should ideally encourage video and photographic evidence of damage to imported machinery instead of sending back damaged parts to China which can be quite expensive and a waste of financial resources.

8.Quality inspection before shipment

When you are importing machinery from China, on-site quality inspection before the shipment is necessary. Otherwise, this mistake can cost you millions. Always make sure that the machine is completely functional and is at par with your set quality requisites.

You can do this on your own or you can hire an inspector who is based in China. Moreover, while on an inspection round, take care that you actually involve real life functional testing.

Normally the manufacturer will have a list of standards that the machine should meet. If not, follow the points in the contract to make sure the machine is the exact one you have ordered.

Functional errors and minor defects can be resolved quickly by the factory workers, if discovered in time. Even if technical issues can be resolved, after delivery, it will cost you dearly.

Are you going to purchase glass machinery from China? Seeking for more advice or need help for quality inspection? Please contact franky@fstechwin.com.