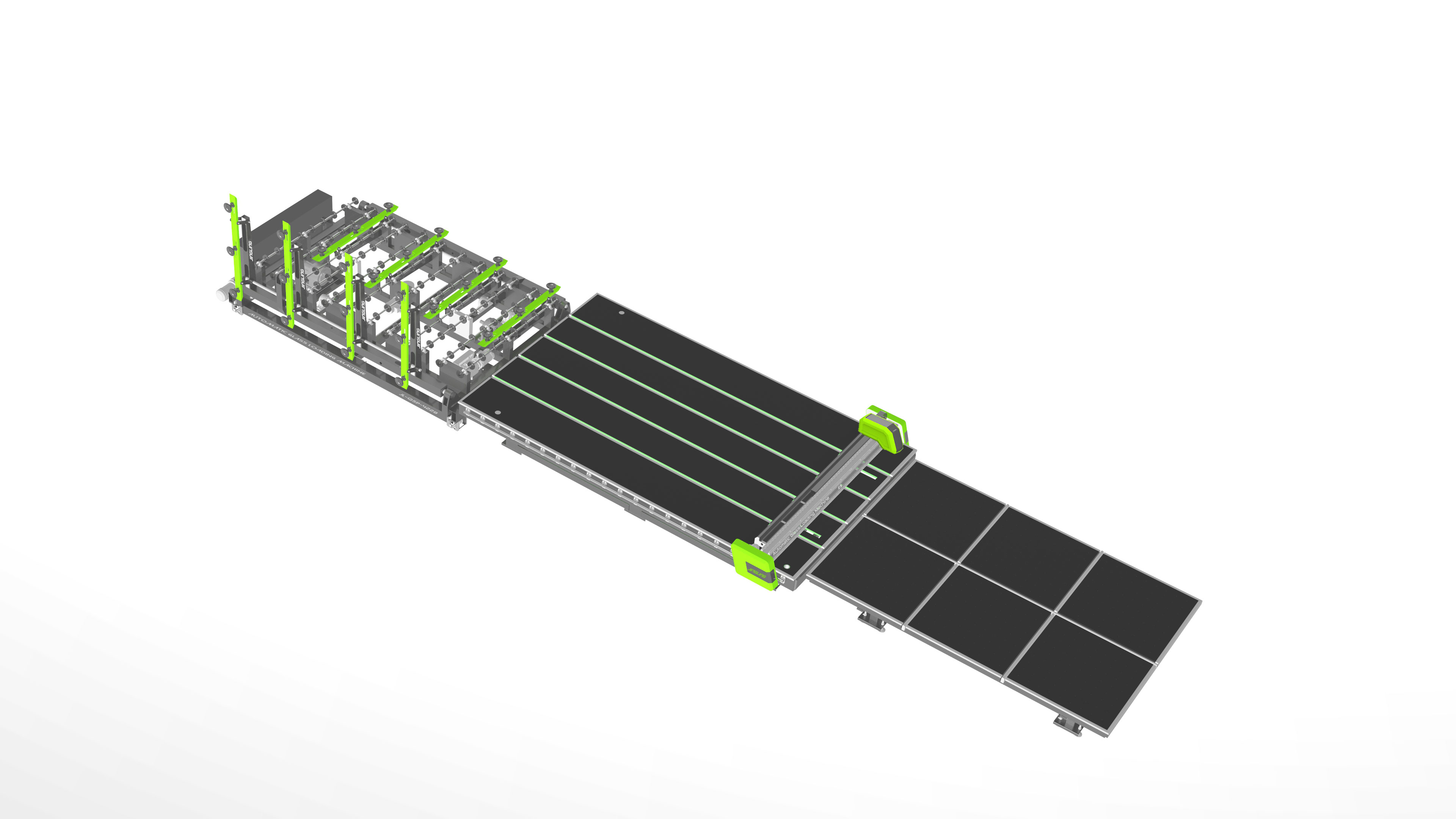

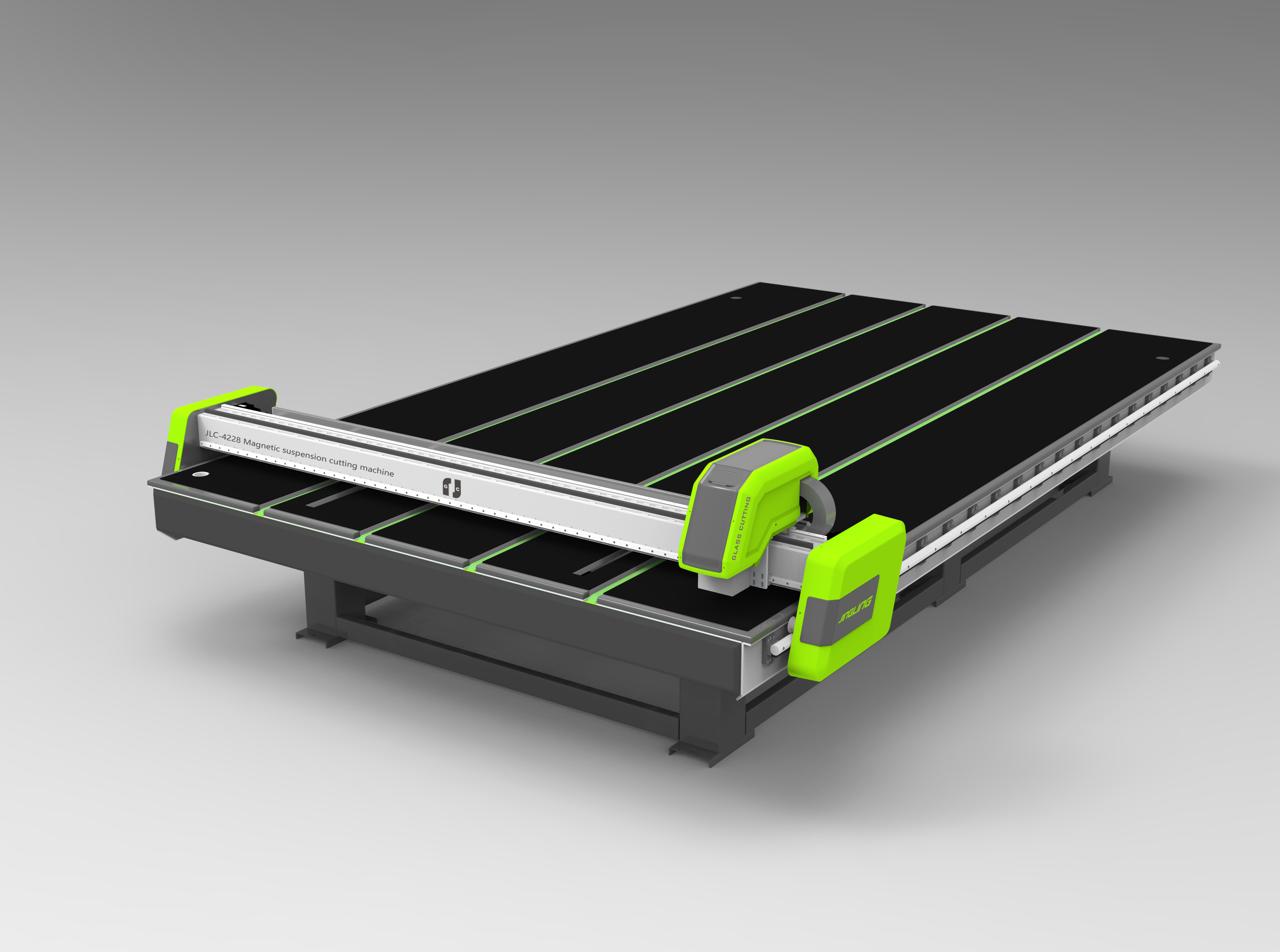

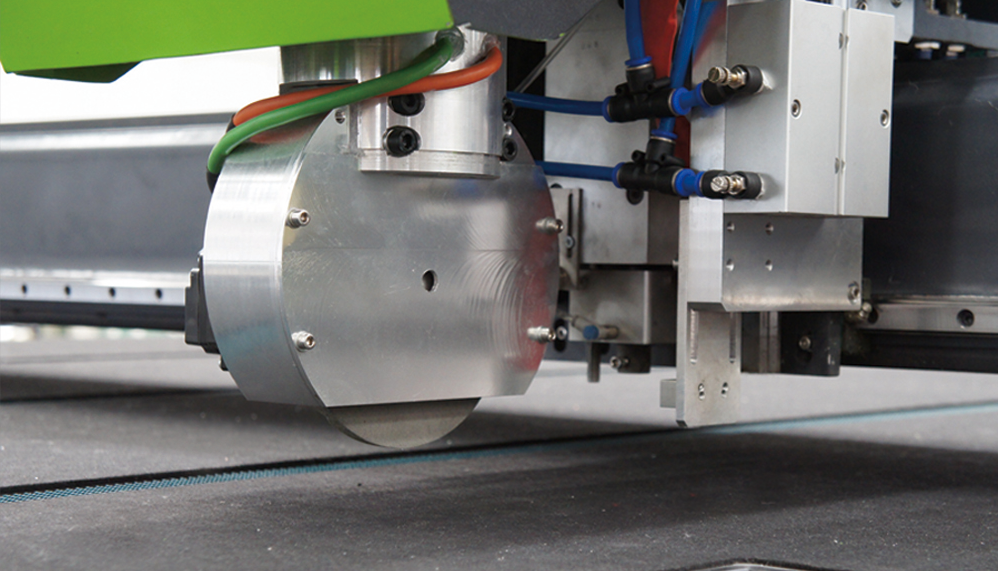

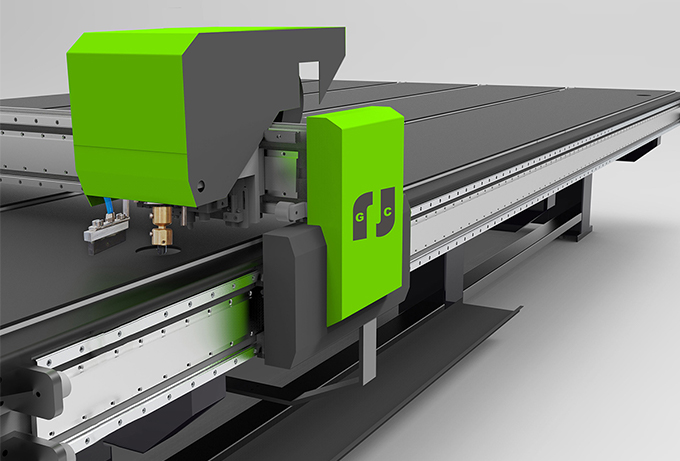

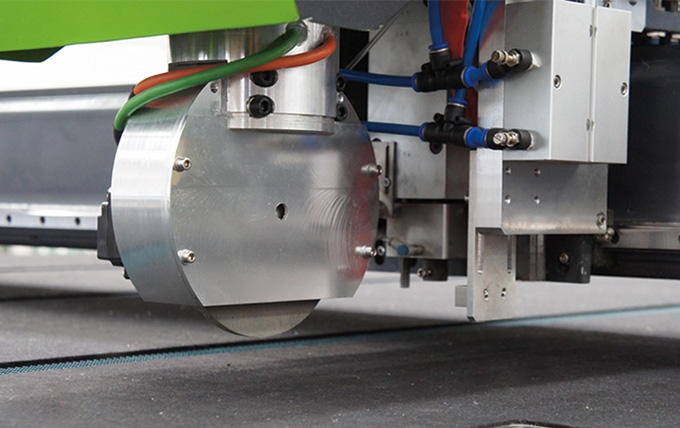

CNC machines provided by Techwin are of top quality from the top factory, whose machines have been widely acknowledged as the first ranked machines in China.

Our industry know-how and expertise have earned us close cooperation relationships with over 1000 factories. The stable machine performance and extraordinary processing efficiency account for their smart choices and success.