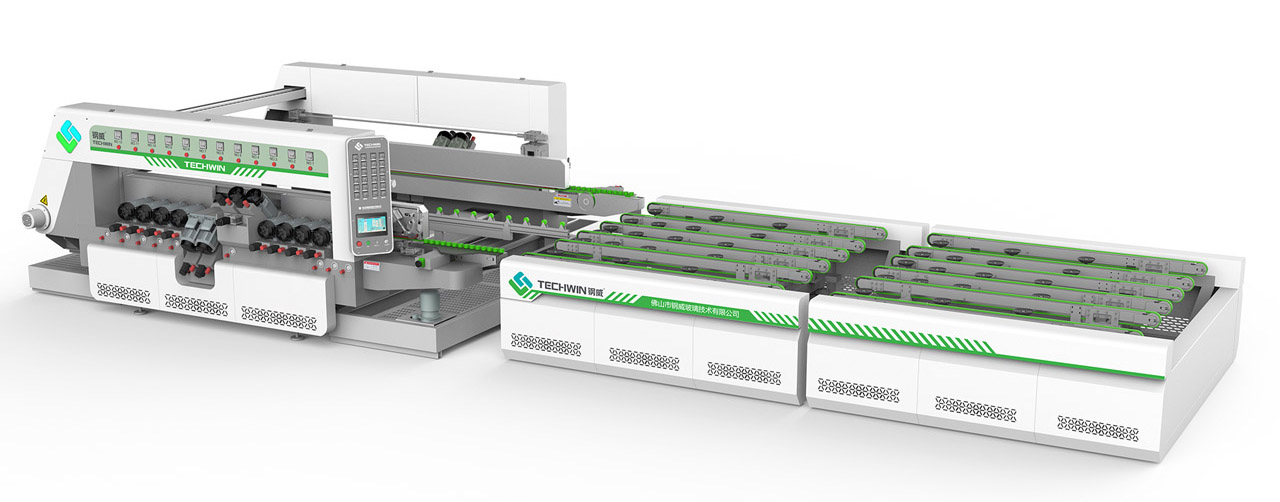

Now double edgers with servo motors for wheels compensation and other parts like opening adjustment and transmission become more and more popular among glass processors. Using glass double edgers with servo motors for grinding wheels offers several advantages and benefits:

–

- Precision and Accuracy: Servo motors provide high-precision control and compensation on glass wheels, resulting in extremely accurate grinding. This ensures consistent dimensions and smooth finishes on glass edges, reducing the need for manual corrections and enhancing overall product quality.

- Customization and Flexibility: The use of servo motors allows for easy adjustment of grinding parameters such as speed, pressure, and angle. This flexibility enables customization based on specific glass thicknesses and edge requirements, enhancing versatility in production.

- Improved Efficiency: Servo motors offer precious for transmission, optimizing the grinding process. This increased efficiency reduces cycle times and enhances productivity in glass processing, leading to higher throughput and reduced operational costs.

- Energy Efficiency: Servo motors are known for their energy-saving capabilities. They consume power only as needed, reducing energy wastage during idle or low-load periods. This not only lowers operational costs but also aligns with sustainable manufacturing practices.

- Reduced Maintenance: Servo motor systems often have fewer mechanical components compared to traditional systems, leading to lower maintenance requirements. This decreases downtime for maintenance and repairs, ensuring consistent production schedules.

- Quality Control and Consistency: The precise control offered by servo motors ensures consistent grinding results across different batches or production runs. This consistency improves overall product quality, leading to fewer rejects or rework, and enhances customer satisfaction.

- Adaptability for Advanced Applications: Servo motor-driven double edgers can be integrated with advanced software and automation systems. This adaptability allows for the incorporation of Industry 4.0 technologies, such as IoT connectivity and data analytics, enabling better process monitoring and optimization.

- Operator Ergonomics and Safety: Modern double edgers with servo motors often come with user-friendly interfaces and safety features. This makes operation more intuitive for operators while ensuring a safer working environment, reducing the risk of accidents or errors.

- Competitive Edge: Utilizing advanced technology like servo motors in glass processing provides a competitive advantage in the market. It allows companies to offer higher-quality products with faster turnaround times, positioning them as industry leaders.

- Future-Proofing: Investing in servo motor-driven double edgers represents a forward-looking approach. These systems are designed for scalability and adaptability to future advancements, ensuring that the equipment remains relevant and effective in evolving manufacturing landscapes.

–

These advantages collectively contribute to enhanced productivity, superior quality, cost savings, and a competitive edge in the glass processing industry.