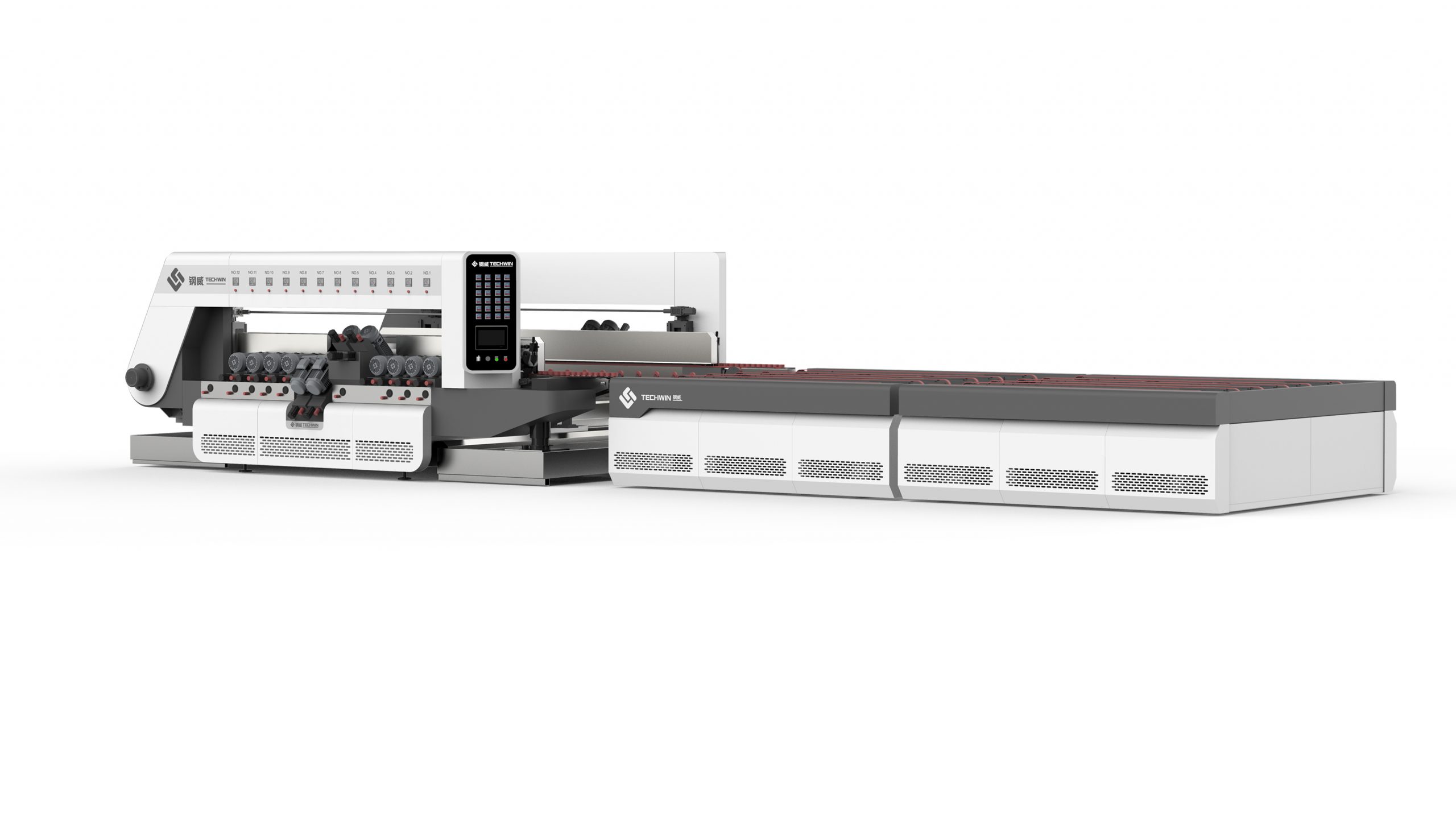

Operating, using, and maintaining glass double edging machines properly is essential to ensure optimal performance, extend the machine’s lifespan, and maintain the quality of the glass processing. Here are some instructions to follow:

Tips for usage:

Regular cleaning: Keep the machine clean from dust, debris, and glass particles. Regularly clean the grinding and polishing wheels to maintain optimal performance.

–

Lubrication: Follow the manufacturer’s instructions for lubricating moving parts, such as bearings and guides, to ensure smooth operation and prevent premature wear.

–

Glass alignment: Properly align the glass panels on the conveyor system to avoid potential collisions or damage during the processing operation.

–

Preventive maintenance: Perform routine maintenance tasks as recommended by the manufacturer, such as belt tensioning, blade replacement, and inspection of electrical connections. This helps prevent breakdowns and ensures consistent performance.

–

Regular calibration: Periodically calibrate the machine’s thickness control systems to maintain accuracy in glass thickness throughout the processing.

–

Monitoring quality: Continuously inspect the quality of the processed glass edges to ensure they meet the desired standards. Make adjustments to machine parameters if necessary.

Maintenance Guidelines:

Cleaning and debris removal: Regularly clean the machine’s components, including the conveyor system, grinding wheels, and polishing wheels, to remove debris and prevent buildup that can affect performance.

–

Lubrication: Follow the manufacturer’s instructions for lubricating moving parts. Use recommended lubricants and apply them at the specified intervals to ensure smooth operation.

–

Belt and chain maintenance: Check and adjust the tension of belts and chains as needed to maintain proper alignment and prevent slippage.

–

Inspection and replacement of consumables: Periodically inspect and replace consumable parts, such as grinding and polishing wheels, according to the manufacturer’s guidelines or when they show signs of wear.

–

Electrical maintenance: Regularly inspect electrical connections, switches, and control panels to ensure they are secure and functioning correctly. Repair or replace any damaged components.

–

Professional servicing: Schedule regular professional maintenance and servicing by trained technicians to identify and address any potential issues before they escalate.

–

Remember, always follow the manufacturer’s specific instructions and guidelines provided in the machine’s manual for operation, usage, and maintenance procedures. Adhering to proper procedures and routine maintenance will help ensure the efficient and reliable performance of your glass double edging machine.