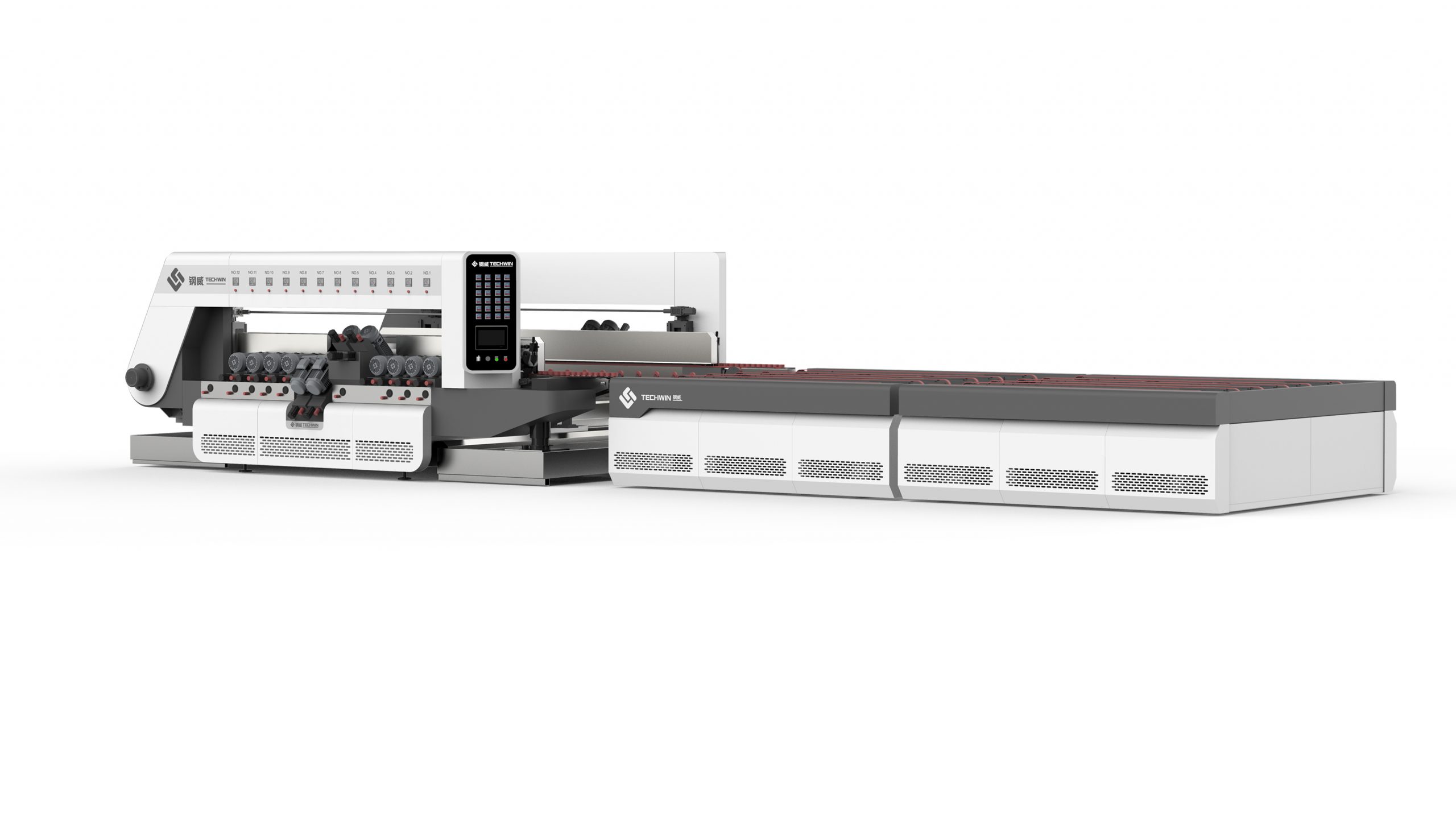

Lubrication

1. Wipe up the machine and daub exposed parts that are without painting or oxidation treatment with anticorrosive oil after work everyday and lubricate grinding carriage slide bar, slide plate and slide base with machine oil.

2. Components of transmission system should lubricated once every 500 hours’ operation and make sure that the intake volume does not exceed the middle of the oil immersion lens; decelerating parts should be injected with calcium-sodium base grease once every 3000 hours’ operation so as to lubricate bearings and gears; worm reducer should be reinjected with 350 industrial gear oil once every 3000 hours’ operation to the middle of the oil immersion lens.

3. Grinding wheels should be dismantled from the Wheel motors every 3 months and waterproof jacket of the motor should be replaced.

4. Components such as wheel bearing, wheel lead screw, wheel gear, gear of main transmission and chain transmission bearing should be lubricated with grease, synthetic calcium base should be lubricating every 3-4 months.

5. All chains should be lubricated once 3 or 4 months. If you have enough experience, you’d better dismantle the chain and wash it with kerosene. After being dried, lubricate it before installation and application.

6. Back & front driving chain and stainless-steel guide rail should be lubricated. Do remember to dismantle the down-hood , left-hood and right-hood first , and lubricate from the corner of driving chain to the driving plate so that the guide way and stainless steel rail can get lubrication as well when the chain turns.

The Usage of Coolant andBrightenerBe sure that cooling water is changed regularly when you adopt circulating water cooling method. Otherwise, cooling water with excessive quartz powder will affect the quality of spinning. Circulating brightener(cerium oxide)should receive some treatments such as sand-separation, filtration, agitation and lubrication-adding. Do remember to change or replace the consistency of cerium oxide regularly, or the quality of brightener will be affected.